Bringing freshly prepared specimens to an apparatus only to find that it is broken is one of the most irksome things that can happen in a lab. No one is pleased, not the students, lab managers and supervisors, because samples, reagents, and time are all squandered. As a result, many laboratory planning consultants often describe the crucial aspects of laboratory maintenance appropriately.

Why Is Laboratory Maintenance Important?

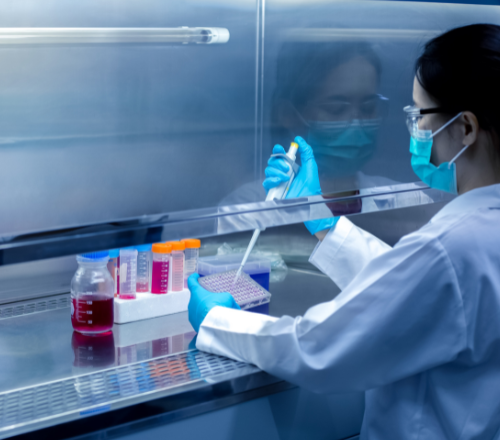

When you run a lab, you know how important it is to keep your laboratory furniture and equipment in good condition for your tests to be accurate and trustworthy. Obtaining precise measurements is essential for the majority of science experiments. An entire scientific investigation can be derailed if your facility and equipment are not maintained. If there is contamination, your test results can also be invalidated. Maintaining a clean lab and equipment is a challenging aspect of working in a lab. It is yet just as crucial as the trials themselves.

The capacity of laboratories to provide reliable results rapidly is crucial. The continued achievement of these objectives depends on effective lab equipment. Maintaining and cleaning lab facilities and equipment is thus necessary.

5 Tips for Effective Laboratory Maintenance

1. Sanitation

Maintaining a clean, hygienic environment is one of the simplest methods to keep your lab equipment in good condition. Surprisingly, many labs still need to complete this crucial work. It is critical to wipe down the exterior of all apparatus daily and perform a complete, in-depth cleaning at least once every week to keep your lab and equipment in excellent condition. Certain equipment types will require a particular cleaning procedure. To guarantee thorough cleaning, refer to the owner’s manual for each piece of lab equipment.

2. Assessment

Maintaining equipment calibration is another laboratory maintenance advice. Failure to do this frequently can cause data corruption and produce inaccurate results from your tests. From simple preventative upkeep to complex accuracy verification processes, calibration can take many different forms. When you regularly calibrate your equipment, getting it back up and running will rarely need more than a few minutes of preventive laboratory maintenance.

3. Reparation

Lab equipment will occasionally deteriorate and stop functioning. Instead of throwing away damaged equipment right away, give it some thought to see if any parts might be changed or things could be fixed. Repairing and replacing parts can be an excellent strategy to extend lifespan and reduce expenses, especially with more significant goods. Some parts will wear out more quickly than others because of the nature of the products, but with proper management, these can be replaced in time to avoid issues or burnout. Think about the ease with which microscope lenses, filtration systems, and centrifuges may be exchanged without discarding the entire apparatus.

4. Renovating

Refurbishing apparatus is a great solution for some equipment in labs that aren’t operating as smoothly as they once did. Each item will need to be disassembled, and the components will need to be thoroughly cleaned. They can be re-lubricated and assembled after being cleaned. Before reassembling, you can find any worn-out components during this process and replace them if necessary. Some of the machinery will function as well as when it is brand new once this process is finished.

5. Reliable Implants

Sometimes, more than necessary, upkeep and repairs will be required to restore equipment to its ideal state. Some lab supplies will eventually need to be replaced. When this occurs, some labs could be tempted to select new equipment that is less costly than their current model to save money. New lab equipment should be carefully chosen. Even though it may be slightly more expensive, high-quality equipment is essential to guarantee that it will be robust and provide reliable results for all your investigations and testing needs. Higher-quality equipment often has simpler access to replacement parts. Additionally, they are frequently simpler to maintain and renovate.

Checklist For Maintaining Laboratory Equipment

1. Routine Cleaning

To remind employees of the daily tasks that need to be completed, such as clearing and cleaning worktops, sanitising their fume hood, sweeping floors, and sanitising the lab’s most used surfaces, it is a good idea to establish an essential housekeeping checklist for the lab.

2. Examine Personal Safety Gear

It is crucial to emphasise that the PPE must be in good shape and high quality before any project begins. Have your personnel periodically inspect the hearing conservation equipment, gloves, boots, and eye and face protection for any signs of wear and tear.

3. Restock The Handwashing Facilities

Handwashing sinks must be kept spotless, and towels and disinfecting soap dispensers should be conveniently located. The issue must be resolved immediately if the sink becomes clogged to lessen the risk of backup and contamination.

4. Upkeep Of The Emergency Stations

Keep emergency antiseptic spray and shower stations under the established guidelines, and take the time to test all station components multiple times per week to ensure proper operation. Plan for a skilled technician to inspect the station regularly.

5. Make A List Of The Items In The Refrigerators And Freezers

The origin and expiration dates of all things that must be kept in refrigerators and freezers should be noted in an inventory maintained regularly. Inventory management and the prompt removal of outdated goods are greatly facilitated by regular rotation.

The Bottom Line

New varieties of laboratory apparatus are introduced to the market every year. Look out for lab equipment you may replace with something more dependable and effective. Some laboratory furniture manufacturers, such as Santech Labs, allow their customers to recommend changes to the equipment so that it is more suited to your particular lab processes.